Post by rainbowfish on Feb 10, 2016 14:00:12 GMT -6

So this is a repeat of a repeat, but it's still worth repeating. Most important thing you can do for your rainbowfish is to change the water and provide quality filtration. This is about the quality filtration part. Those of you in Europe are going to be saying to yourself, duh, this is so obvious and we've been doing this for years. Yeah, you're right. Stephan saw that we were a bit slow here in the States and brought the needed items to the States. Not many people would have the guts to import an entire shipping container full of foam!

-------------------------------

Below is a repeat of an article I wrote for another forum several years ago. Now that Stephan Tanner (http://www.swisstropicals.com) is going to be our speaker I thought you might want to take advantage and order some foam from him. He is driving down so shipping is Free, until the car is filled!

There has been a bit of back and forth on Matten Filters and some misinformation so I thought I might start a thread dealing strictly with this subject. I must say that my friend Klaus Schoening has been telling me about these filters for about 3 years now and it finally took a visit to Stephan Tanner’s fishroom to really show me what he was talking about. You can see some of the ways that Stephan uses the filter material on his site www.swisstropicals.com/ It’s also a good place to buy the quality foam material. Go to his site to read more on the quality of foam. His sheets ~ 39” x 39 inches can make 9 13” x 13” x 2 inch thick filters, which fit into a lot of my aquariums very nicely. The cost of one sheet is $100 at least for the medium density blue foam. Some of the other types I think are a bit more expensive.

Some of the misinformation on this site was that the filters are so expensive. I guess that would be true if you were just cutting it to fit one of the sides of your aquarium or using it as a divider. This could get very expensive for something like 10 gallon tanks. When I was at Stephan’s I saw another way that he was using the foam, making a “small aquarium” filter inside. You use a portion of two walls of the aquarium and add a third wall with a piece of 4 inch wide glass. You make the length of the glass slightly higher than the water level and silicon it into place. The fourth “wall” of the aquarium is a piece of foam that is slightly wider (1/2 to ¾ inch) than the distance between the one wall and the added piece of glass. You cut the foam to a height that is going to be just slightly higher than the water level in the tank. You don’t want any fishes swimming over the top and into the back compartment. With a four inch piece of glass and a 2 inch thick piece of foam jammed in place you have a back filter compartment that is about 2 inches wide. For my 13 inch pieces of foam a 2 x 12.5 x ~ 12.5 area which is where you can store a heater and which also has room for the filter riser. The filter riser is simply two pieces of ¾ inch PVC pipe plus a 90 degree corner to hold them together. You make the vertical PVC pipe long enough so that it’s about ½ inch from the bottom of the tank. The small piece that is parallel to the water’s surface is about 3 inches. A 7/32 inch hole is drilled near the top of the vertical pipe in a downward direction so that the airline tubing will slip easily down the pipe. I’ve improved Stephan’s filter by adding an ASI-1 diffuser (.5 x .5 x 1.5” Sweetwater, available thru Aquatic Eco Systems) to the end of the airline. I do the same thing on my hydrosponges which adds a lot more air to the water and eliminates that very annoying glug-glug in the fishroom.

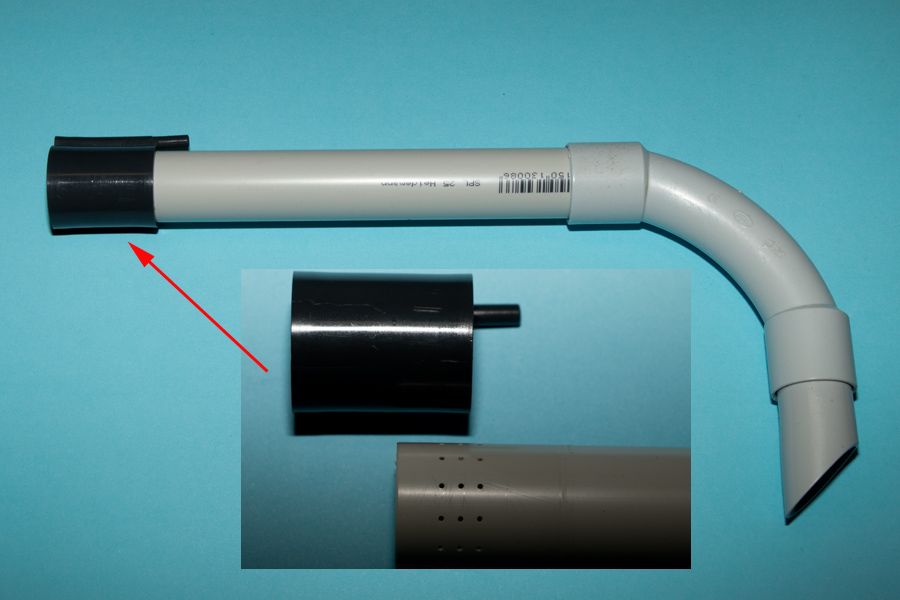

***Update - When I'm wrong I admit it. Use the info above to make your own DIY riser tube but know that Stephan's jetlifters (25 mm size) are amazing. www.swisstropicals.com/filtration-shop/jetlifter-cubelifter-shop/ I tried one and then switched out all of my home made ones to this style. The rounded curves instead of hard right angles allows the water to move thru faster and thus a higher volume for the same amount of air flow. The tiny holes that he has drilled on the bottom of his jet lifter REALLY helps push the air through. It is really easy to clean and it rarely gets clogged. I think I'm doing this like once every 3 months. So make your own if you must but start saving and buy the jetlifters later. You know if you do it right the first time you won't have to do it over like I did!

Photo of jetlifter tube and closeup of holes

Compare the volume of filtering material of a Matten Filter to the Best Sponge filter on the market – the ATI hydro sponge.

I typically use a #III (for 10 gallon and 20 gallon tanks) or #4’s. A #3 is supposed to be for a tank up to 40 gallons so I am using them at 2x filtering capacity. On my breeder flats I use 2 #4’s. The volume for a #3 is 34.5 cubic inches. The volume for a #IV is 46 cubic inches or 92 cubic inches for two in my breeder flats. If I replace the two IV’s with a 13 x 13.5 x 2 inch piece of foam I now have 351 cubic inches or almost 4x as much filtering capacity. It’s not a big deal in a lightly populated tank but in a tank with a big population of fish a bigger biological filter is better.

Anyway on to a few photos of items needed and some shots to give you an idea of what I’m talking about. Tools

I don’t want to make this a lesson in how to cut glass but if you want straight lines every time use a glass cutter that has an alignment tool built in as shown in this photo (8 o’clock). You can buy them at stain glass window supply companies. I’ve cut tons of glass tops so this $30 cutter has more than paid for itself. The little baby food jar contains a few small rags soaked in kerosene. Every time you make a score with the cutting wheel you must moisten it with a little kerosene by quickly rubbing it on the wheel. Otherwise you will quickly wear out the cutting wheel and start making very poor cuts. This is where most people go wrong cutting glass. It goes w/o saying to wear safely goggles as you can’t see your rainbowfish if you are blinded by a piece of glass that popped accidently into your eye! A file is handy to gently rasp the sides of cut glass when you are thru. You don’t want to put a sharp piece of glass in your aquarium that will cut you and your fishes. File it under a stream of water and it will be much smoother, again wearing those safety glasses. Masking tape is good for holding the glass in place while you are cutting it. Naturally a ruler so that you can accurately mark where you are going to make your score. I have a small glass cutter (7 o’clock) that I use to take out a small notch in the glass and to gently tap the score line in the glass to ensure an even break. A good pair of pliers to help with an even break in the glass (12 o’clock). You need a nice sharp long box cutter type blade to cut thru the foam (2 o’clock). I use a drywall T (not shown but see Stephan’s site) to make a straight clean cut thru the foam. A ragged cut, especially at the bottom of your foam piece can allow small fish to squeeze underneath it. A new relatively cheap tool is the PVC pipe cutter (5 o’clock). Stephan showed me this and how easy it was to use. The $10 one I bought at Lowes doesn’t really make perfectly perpendicular cuts but for filter parts it really doesn’t matter. I use Schedule 40 PVC weight tubing ¾ inch diameter.

Materials

Left to right

Mesh to cover return on filter riser ~3mmx3mm, or 1/8th inch plastic mesh. Much bigger holes than used in screen doors, available at any hardware store.

Completed Riser – AS-1 difusser is pulled out the bottom to show it but is inside pvc during normal operation. Screening material is held in place by a plastic cable tie. Screen is trimmed as well as the excess cable tie. Cut the length of your pipe so that it is slightly off the bottom of the tank or above the gravel line.

Glass “wall” – a 4 inch wide piece of glass will give you enough room for a heater to hide if you want. I’ve cut them as small as 3.5 inches but 3 inches is getting a little tight. I use thick glass (3/16th inch) because I want a piece of glass that isn’t going to break and cut me if I wack it. Even so Stephan tells me that it’s not thick enough to be able to take the pressures of the sponge pushing against it. He uses a ½” x ½ inch angle made from aluminum. It doesn’t have to be the entire length of the glass, as shown in this photo. This gives you some extra area to glue to the back wall of the tank to make sure that your new wall isn’t going to move. Worried about aluminum in your tank? Dr. Tanner doesn't and so far the results in his fish room have been nothing less than outstanding. Glue it to the glass so that it will be on the inside of the box so you won't have to see it every day and making it look neater too. Oh, don’t forget to cut a small notch in the glass at the bottom to account for the space of the silicon seal at the bottom of the tank. If you make your notch too big you’ll just plug the hole with silicone glue anyway when you put the wall in place. You can see a closer image of this glass piece below.

When it comes time to silicon glue the piece of glass into place add a generous strip of glue to the side and bottom edges of the glass and angle of aluminum. Have your tank marked ahead of time at the top of the tank and on the bottom so that you can quickly put the wall into position. Get out a ruler and make sure that the back of the glass piece is say 12.5 inches from the wall and the front of the glass piece is 12.5 inches from the wall. You want a nice straight perpendicular wall so check while the silicon is still soft. Make sure you fill that tiny gap in the back where you notched the glass. Once you are pretty sure it’s in place lick your index finger and then use it to smooth out the silicone. It won’t stick to the glue as easily making a neater job. Use another finger if you need more area to smooth. You don’t want to be licking the same finger twice :-).

If you are working with a 13 inch wide piece of foam then glue the wall into the tank so that it’s ~ 12.5 inches wide. You can squeeze the foam so that it fits snugly into place and fish and dirt can’t squirt around the sides. To keep the riser tube in place make an every so slight notch cut in the foam. I hope you can see the finished product in the photo below.

I took it from this angle so that you could especially see the added glass wall. You can see the bubbles from the riser in the upper left hand corner.

Below are two photos from Stephan’s tanks using the same principle. In one tank he is using a powerhead to drive the filter. Since I have the best air pump (linears) I use air to drive my risers. Stephan uses air to run the majority of his matten filters too.

The next photo shows the front view of one of his risers driven by air. The water level is below the top of the sponge, the water on the lid of his aquarium make it look like it might be higher.

If your tanks are going to require taller pieces of foam I would suggest you plan out exactly how you are going to cut it so that you can get the maximum amount of filters made for your money. In tanks where I have a lot of young fish growing up 2 # IV hydrosponges just couldn’t keep up. So far the new matten filters are working quite nicely. I don’t know if I will convert all of my tanks and almost for sure not the 10 or 20 highs in my fishroom. The hydrosponges are working fine in there. I hope that this bit of info will encourage you to try it our for yourself. Perhaps get together with a friend and split a piece of foam if you don’t need a full meter square worth of material. I think Stephan also sells smaller pieces.

Update: It's been several years since I wrote this article and I've gotten rid of many of my 2' breeder tanks and am now using 3' breeder tanks - 36" x 18" wide by 17" tall. I haven't equipped these yet with matten filters but plan to. I think I am going to use Stephan's idea and make a corner filter though. I'll use the glass pieces like he's suggesting. Aluminum angles do work but the glass looks SOO much better, see here www.swisstropicals.com/filtration-shop/cornerfilter-shop/

Cheers,

Gary Lange